Quality Control

K. Y. Metal understands the importance of quality control. We take the concept of Total Quality Management (TQM) as our main approach as we deal with quality control:

- Quality is defined by customers' requirements.

- Top management has direct responsibility for quality improvement.

- Increased quality comes from systematic analysis and improvement of work processes.

- Quality improvement is a continuous effort and is conducted throughout the organization.

We believe that by executing and maintaining a strong quality control infrastructure, continuous employee training programs, and continuous investment on the latest measuring equipment, we can achieve products with the highest quality possible.

From Raw Material incoming to products shipment, we manage every step of the manufacturing process to ensure products are made to the clients' specifications. All products must go through 3 checks in the production process:

- Raw material inspection

- In processing inspection

- Outgoing inspection

Insisting on top quality is our first priority, and quality stability has earned us the trust of our customers for years.

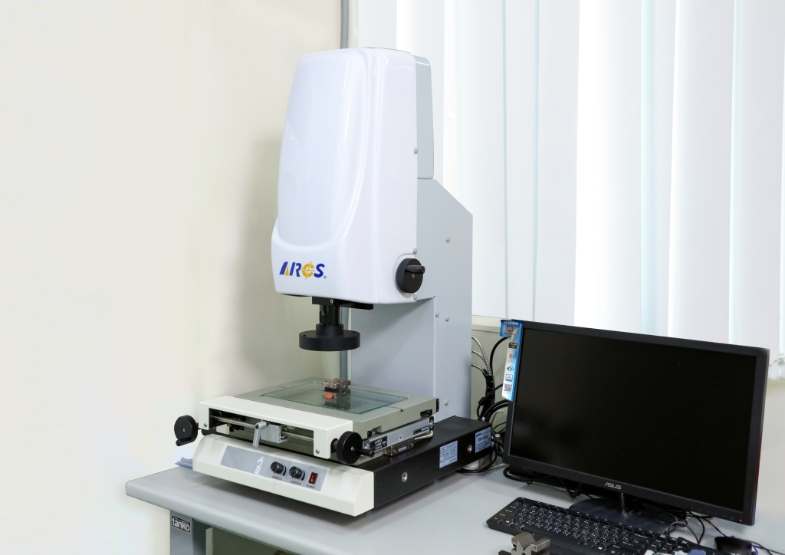

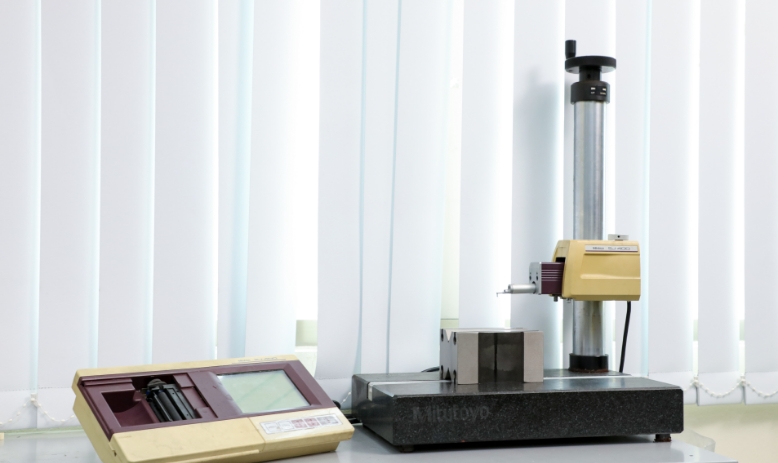

QC Equipment:

- Mitutoyo Contour Measuring Instrument

- Mitutoyo Surface Roughness Tester

- 2.5 D Optical Comparator

- Mitutoyo Toolmaker's Microscope

- Pin Gauge

- Ring gauge

- TESA Micrometers, Calipers/Verniers, Cylinder Gauge

- Universal Punch Corp. Concentricity Gauge

- Nakazawa Rockwell Hardness Tester